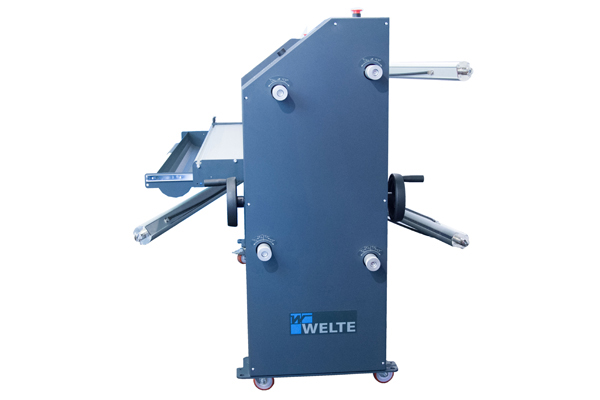

WELTE 62 Pro S

Welte 62 Pro S – a further development of the Seal 62 Pro S.

The laminator concept of the Seal 62 Pro S, which has been successful for over 15 years, has

been further enhanced. The basic concept has been retained, but practical improvements and

contemporary changes have been implemented. Among other things, the new laminator has

been equipped with more modern electronics.

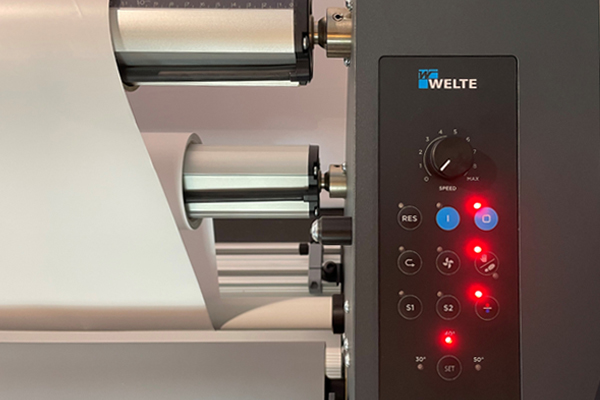

The new control is easy to use and all important parameters can be set by touch screen.

The maximum speed for the operation of the laminator has been increased up to 12m/min.

The well-proven mechanical technology and the two rear pivoting shafts have been retained.

The technically approved roller concept with high contact pressure is identical to the previous

model. So experienced and also unexperienced users will we able to work very productively

with the Welte 62 Pro S laminator with perfect results.

NEW: The three rear and front swing-out shafts allow easy material loading

NEW: integrated Wi-Fi/LAN. Remote Monitoring of vital machine data

heatable top roller (max 140 ° C)

maximum speed of 12 m/min

High contact pressure enables excellent cold lamination results,

especially for the demands of traffic sign production

Modern touch screen for simple operation, where the main parameters like

roller pressure, roller nip opening and the roller heating are displayed

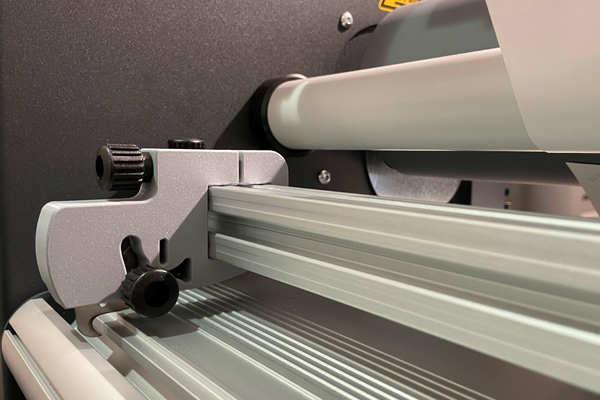

auto grip supply shafts for user friendly material loading

auto grip re-wind shafts for more effective take up of release liners

outboard brakes for greater control of material unwind

WELTE 62 Base

The universal laminator for quick, easy mounting and laminating work, as well as the application of double-sided adhesive film and application tape.

The system’s advantages are particularly evident in its clear concept aimed at user-friendliness and in the quality of the rollers with a special, not too hard rubber mixture.

The maximum passage height is 40 mm. The maximum processing speed is stepless adjustable up to 5 meters per minute.

The rollers have a diameter of 116 mm and are equipped with a non-stick coating.

The upper roller is raised and lowered pneumatically, the pressure is variably set with a pressure regulator, the pressure is displayed with a pressure gauge.

The 3 material shafts (optionally 4) ensure easy handling and quick changing of the material.

The upper roller can be pre-programmed to be heated to 30/40/50°C.

Clear, manageable machine concept allows for easy handling

Quick and easy changing of material

Versatile system for all standard applications in advertising technology