Welcome to Welte.

Supplier of machines, accessories and materials – all for your large format workflow.

Visit us next at:

Machines for every project

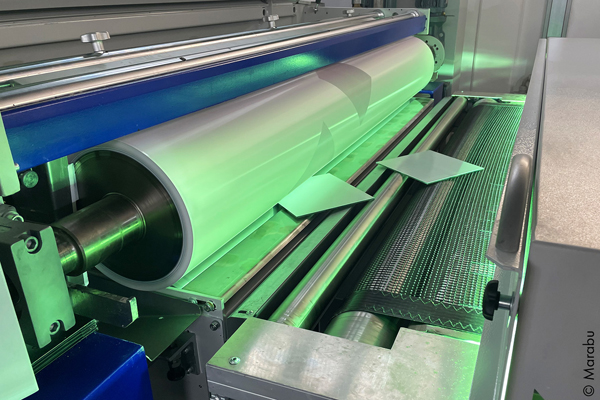

Finishing

We offer you everything that the market of professional lamination can currently expect. Hot and cold roll laminators, liquid laminators, innovative UV coater, calender for textile finishing and a complete range of films, adhesives and accessories.

Further Processing

Only with the finishing your own large format workflow is complete. The Welte range of cutting systems, welding machines, sewing machines and eyelet punches offers maximum performance for every size of company and every application.

Materials & Equipment

Ensuring a complete range of high-performance consumables is very important to us. So we concur with our systems a contribution to your success.

Future-Oriented Company

Welte GmbH offers everything for the large format workflow: From consumables for digital printing to finishing and further processing, we work exclusively with leading manufacturer brands in every single market segment. Our range of machines, media and consumables offers a suitable solution for every size of company, every production requirement and every application. As a perfectly coordinated complete package or as a modular addition to your existing workflow – always keeping the latest trends and technologies in mind.

Holistic Consulting

Our claim is best service and highest customer orientation. Therefore, we only offer our customers products and services

that are tailored to their needs and the respective market requirements.

Competent Partners

We act as a national contact for our end customers, are Europe-wide distributors and rely on close international cooperation with our partners.